The agricultural landscape is evolving, and so is AFGRI Equipment’s commitment to offering the best tools for the job. We are thrilled to announce our new partnership with Jupidex, import and support agents of high-quality hay equipment. With a rich history in support and training, Jupidex brings a range of products to our portfolio that is set to revolutionise hay production for our clients in the Western Cape.

McHale Round Non-Chopper Baler F5400

The McHale Baler 5400 stands as a testament to McHale’s commitment to excellence. Engineered for those who demand more from their equipment, this model ensures both consistency and reliability. Whether you’re dealing with silage, hay, or straw, the 5400 promises dense and well-shaped bales every time.

The McHale 5400 is a semi-automatic, non-chopper Fixed Chamber Baler, equipped with a star-shaped feed rotor to move crop quickly and efficiently from the pick-up into the bale chamber, maximizing bale throughput and performance.

Key features:

- Advanced net wrap system. The high-performance variable pre-tension netting system has been designed and developed for the F5000 fixed chamber range.

- The heavy-duty 2.1m pick-up is fitted with lateral feed augers that smoothly guide the crop into the chopping unit. This galvanised pick-up lifts even the shortest of crops.

- The 5400 is equipped with a Wizard Control Console containing all the functionality required to operate the machine.

McHale Round 15 Knife Chopper Baler F5500

A step up in the baler hierarchy, the McHale Baler F5500 offers farmers a perfect combination of efficiency and output. Known for its versatility, it caters to various crop types without compromising on bale quality.

The McHale F5500 is a semi-automatic, 15-knife chopper Fixed Chamber Baler, which comes fitted with automatic progressive greasing as standard. It is equipped with a Wizard Plus Control Console, which allows the operator to control features such as drop floor and knife position. Bale density can also be adjusted on the machine. The machine is fitted with 500/50-17 tyres as standard for superior flotation.

Key features:

- Precision chop system. As the crop enters the spiral rotor, pairs of rotating tines feed the crop through the chopping unit.

- High-speed pickup and rotor. With all 15 knives engaged, a theoretical chop length of 65mm is delivered. Knives can be engaged and disengaged from the tractor cab.

- The drop floor unblocking system, which is combined with other high-specification components, ensures long life, reliability, and a machine that is rugged enough to handle the toughest of crops and ground conditions.

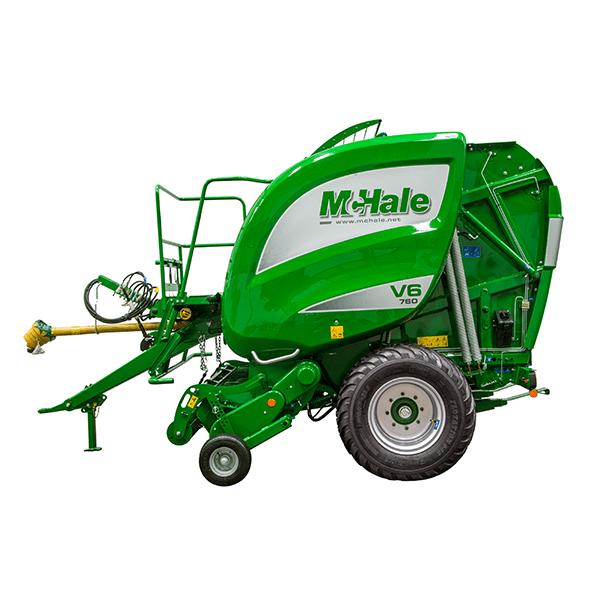

McHale V6750 15 Knife Chopper Variable Chamber Baler

This semi-automatic variable chamber baler can produce bales from 0.6 to 1.68m.

The V6750 is fitted with a 15-knife chopper unit and heavy-duty rotor. A double-drive system aids belt rotation and bale formation to allow the machine to operate in the toughest of conditions.

The net and bale density can be adjusted from the cab through the Expert Plus control console. The machine is fitted with 500/50-22.5 tyres as standard and comes with centralised grease blocks.

- A 540 rpm Split Drive Gearbox is fitted as standard. This gearbox design ensures that power is evenly distributed to both sides of the machine.

- The bale chamber is comprised of heavy-duty endless belt(s). The belts are extremely hard-wearing and are reinforced with synthetic material, which ensures that the belt(s) can absorb and apply high pressure to the material in the Bale chamber.

- The McHale V6750 is fitted with an Expert Plus control console, which has a large graphic display.

Fusion 4 Plus Integrated Bale Wrapper

The McHale Fusion 4 Plus is a fully automatic integrated baler wrapper that can apply film or net wrap to the barrel of the bale, delivering optimum bale shape and bale density. The Fusion 4 Plus can provide high-quality fodder through the use of the film binding system, resulting in better silage quality and easier feed out.

The machine is equipped with a patented bale transfer system and a vertical wrapping ring. These two McHale patents deliver maximum output whilst keeping the machine short and compact at 5.8 metres in length. The machine is equipped with a 25 knife-chopping unit and uses ISOBUS software.

- In-cab adjustments: The ISOBUS control terminal allows for bale density to be adjusted from the comfort of the tractor cab. Drop floor unblocking: The drop floor unblocking system is fitted with an automatic unblocking function as standard.

- Highest output pick-up: The Profi-Flo pick-up has been designed to increase crop intake through more efficient crop flow and has been engineered to ensure end users are operating with a high-performance pick-up that is designed to suit various working conditions.

- Patented high-speed bale transfer: Fitted with a Servo Operated Load Sensing Control Valve which, makes the baling and wrapping process fully automatic.

Kverneland 4336 Mower Conditioner (MoCo)

The Kverneland Mower Conditioner, fondly known as the MoCo, is a favourite among hay and alfalfa producers. It guarantees faster dry-off times by effectively conditioning the crop while mowing. Its design ensures clean cuts, minimizing soil contamination.

Trailed mower conditioner with centre pivot drawbar.

Including features such as a semi-swing conditioner, low maintenance cutter bar, SuperFloat suspension, BX Auto-Swather belt (optional), and FlipOver wide-spreading (optional), the Kverneland 4336 is ready to meet every request with exceptional performance.

Key features:

- Cutterbar with round discs. The round discs have always been a known Kverneland hallmark. The unique circular design means that a constant distance is kept between the outer edges of the disc. Stones are expelled immediately before risking blockage, which reduces shock loads on the transmission to an absolute minimum. This in turn improves durability and maintenance substantially.

- Gentle roller conditioning – for the fragile crop. Roller conditioning provides gentle, yet effective handling of fragile crops such as alfalfa or clover. Roller conditioning effectively cracks stems and their wax coating, while preserving the nutritious leaves. This in turn facilitates an even drying pattern and utilization of the forage.

- The patented ‘SuperFloat’ flotation suspension system allows for maximum protection. The weight on the ground is only approximately 40-50 kg on each side of the cutter bar, resulting in far less skid wear and stubble damage.

4 Disc Mower Kverneland 2624

The 4 Disc Mower 2624 Kverneland is a game-changer. Designed for utmost efficiency and precision, it ensures rapid mowing while preserving the quality of the crop. Its low maintenance requirements make it an ideal choice for farmers looking for long-term utility.

Key features:

- Patented break-out action The fully welded cutter bar with round discs gives a very stiff and strong design for high durability.

- Fitted with a non-stop BreakBack system to protect the cutter bar. This integrated system will protect the cutter bar from foreign obstacles.

- Quality mowing through hydraulically centre suspended design facilitates a cleaner cut, better protection of the stubble, and in addition an improved fuel economy, as well as less skid wear.

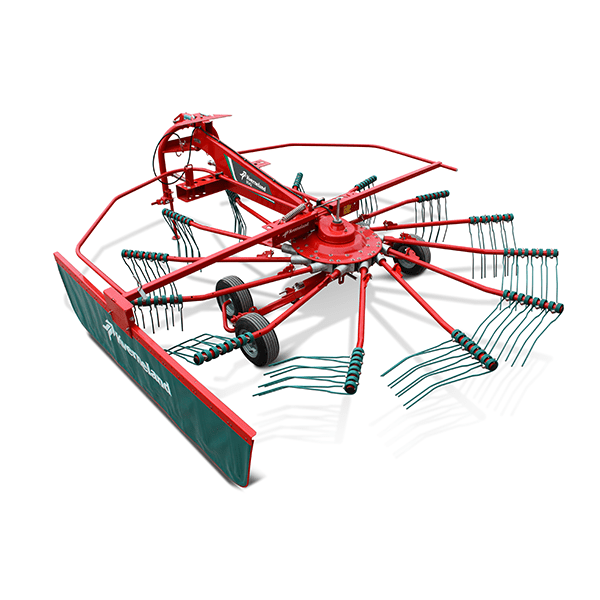

Kverneland 9542 Hay Rake

The Kverneland Hay Rake is a powerful tool for collecting hay, ensuring minimum contamination and maximum bale quality. Its design promises optimal crop flow and reduced losses.

Kverneland 9542 is a high-performance rake with a drive system designed to last long. The 3-pt headstock allows the rake to follow the tractor around tight curves. The standard boogie wheels offer perfect ground contour following and minimise the amount of dirt that collects in the swath. The Kverneland 9542 comes with a standard hydraulic height adjustment called “HydroLift.”The HydroLift allows you to set the rake to different field conditions. You can quickly set the raking height from the tractor cab to suit the stubble length or varying ground conditions.

Key features:

- Adjustable curve disc and working width.

- Tandem axles offer perfect ground contour followings.

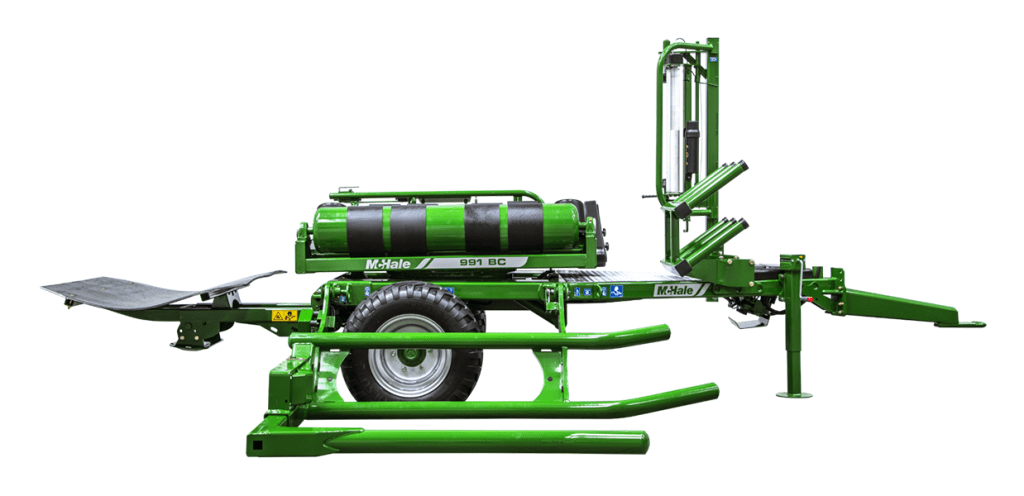

McHale 991 BC Wrapper

For preserving the nutritional quality of your bales, the McHale Wrapper stands unparalleled. Its advanced wrapping system ensures an airtight seal, optimizing the fermentation process and increasing fodder quality.

Key features:

- Ground-supported damper system – The patented bale damper system gently lowers the bale to the ground while eliminating any stress on the chassis of the machine.

- High-speed wrapping table. The wrapping table is constructed of four heavy-duty, endless belts that ensure smooth and consistent bale rotation, even when dealing with loose or poorly shaped bales.

- Cut and hold system – At the end of the wrapping cycle, the hydraulically operated cut & hold system cuts and holds the film in position ready to wrap the next bale.

McHale R5 Round Bale Handler

The McHale Grabber is a testament to practical design. Ideal for bale handling, its robust design ensures minimum damage to the bales while maximizing efficiency. The McHale R5 is ideal for transporting bales, which have been tipped on their ends in the field. It can also be used to collect bales after wrapping rotate them 90 degrees and stack them on their ends so that they hold their shape better.

Key features:

- Soft hands technology for delicate handling. Designed to cradle the wrapped round bales without damaging the plastic wrap.

- The R5 round bale handler can also be used to handle unwrapped round bales or load round bales onto linkage wrappers.

- The R5 has a heavy-duty ram fitted with a check valve, maintaining a consistent grip of the round bale as it is being transported.

AFGRI Equipment’s new partnership with McHale and Kverneland offers farmers a range of top-tier hay equipment designed for precision, efficiency, and longevity. We invite you to experience the McHale and Kverneland differences firsthand.

For more information on the McHale and Kverneland range or to schedule a demo, contact AFGRI Equipment today.