Looking to maximize efficiency and yield in your next harvest?

Consider upgrading to the Ultimate Technology Package, which features Predictive Ground Speed Automation. This innovative system leverages cutting-edge technology to optimize your harvest.

Here’s how it works:

- Dual, forward-mounted stereo cameras: These cameras constantly monitor crop height and volume in real-time.

- Pre-harvest satellite field images: Combined with the data from the cameras, these images create a predictive field map.

- Automated speed adjustments: Based on the collected data, the system automatically adjusts the S7’s ground speed to match the varying crop density.

This translates to:

- Reduced operator workload: The system automates adjustments, allowing you to focus on other aspects of the harvest.

- Improved efficiency: By maintaining optimal speed, you can cover more ground in less time.

- Reduced grain loss: Consistent speed helps to minimize grain loss due to bouncing or over-acceleration.

- Maximized yield: Efficient harvesting ultimately leads to higher overall yields.

Upgrade to the Ultimate Technology Package today and experience the future of precision harvesting with Predictive Ground Speed Automation!

4 New intelligent models

The S7 Series boasts four exceptional models: S7 600, S7 700, S7 800 and the S7 900. Each model is designed to cater to specific needs, ensuring that farmers have the power and efficiency required for their unique operations.

The S7 600:

· 382 max engine horsepower

· 3.6 bu/s (126.8 liters/s) peak unload rate

· 300-bushel (10,057-liter) grain tank

· PowerTech™ 9L Engine

The S7 700:

· 460 max engine horsepower

· 4.2 bu/s (148 liters/s) peak unload rate

· 300-bushel (10,057-liter) grain tank

· PowerTech™ 9L Engine

The S7 800:

· 540 max engine horsepower

· 4.2 bu/s (148 liters/s) peak unload rate

· 400-bushel (14,095-liter) grain tank

· PowerTech™ 13.6L Engine

The S7 900:

· 617 max engine horsepower

· 4.2 bu/s (148 liters/s) peak unload rate

· 400-bushel (14,095-liter) grain tank

· PowerTech™ 13.6L Engine

Notably, the S7 600 & S7 700 share the same volume grain tank and engine, while the S7 700 & S7 800 & S7 900 share the same peak unload rate, and the S7 800 & S7 900 have the same volume grain tank.

Moving on to the Exciting New Digital Updates:

- Automation:

Predictive Ground Speed Automation:

The S7 uses the two forward, cab mounted stereo cameras to measure the crop height and volume. Pre-harvest satellite field images are generated to display a predictive field map and the combine uses this data to automatically adjust ground speed before entering changing crop areas. This automation helps you increase your combine productivity while minimizing grain loss.

Harvest Settings Automation:

Harvest Settings Automation takes precision farming to the next level by automatically adjusting critical parameters such as rotor speed, fan speed, and concave, chaffer, and sieve clearances.

Operating this tool is a breeze through the G5Plus display. Farmers can set their preferred limits for grain loss, foreign material, and broken grains. Once these thresholds are established, the combine takes charge, making real-time adjustments to optimize performance.

The significance of Harvest Settings Automation lies in its ability to expedite the harvesting process. By reducing the need for constant monitoring and manual adjustments, it allows farmers to focus on the task at hand – harvesting efficiently and effectively.

Should the set limits be exceeded, the display provides clear insights into the adjustments being made and the reasons behind them. This transparency ensures operators remain informed and in control throughout the harvest.

Included in harvest setting automation are the following technologies, Machine sync, Harvest IPM and Active Yield™.

Machine Sync: This feature allows the combine operator to take control of the grain cart operating in tandem. In-field data sharing facilitates the exchange of critical information and guidance lines among multiple operators, promoting teamwork and efficiency.

Harvest IPM (Intelligent Power Management): Harvest IPM unleashes the full potential of the engine by enabling operators to set power limits up to 105% at rated speed. It acts as a power booster, optimizing energy utilization during grain pumping and other demanding tasks.

ActiveYield™: A system that measures the grain in the cart, ActiveYield™ eliminates the need for manual calibrations. It ensures accuracy by automatically calibrating as the tank fills, saving time and enhancing efficiency.

2. POWER & PRODUCTIVITY:

Crafted to conquer the toughest conditions, the John Deere PowerTech™ , 13.6L, turbocharged 830 cubic inch power plant stands as the driving force behind this agricultural titan. It delivers maximum rated power at a lower engine RPM, providing not only robust performance but also ensuring engine longevity.

Fuel efficiency takes center stage in this power-packed narrative. The S7 Series doesn’t just offer power; it does so with a remarkable 10% reduction in fuel consumption.

John Deere is committed to elevating your productivity, and with this combine, they’ve perfected every detail:

Improved Grain Loss Sensing system with double the number of sensors, giving you more accurate loss sensing. Any changes in the loss rate, can be seen in your display.

The Premium PowerCast™ Residue System uses a combination of straight blade knives and a mechanical drive to deliver an even residue distribution up to 45 ft (13.7 meters), while conserving up to 15 horsepower increasing your productivity.

The Adjustable Auger Spout can now be adjusted from your cab. This makes it easier to fill carts or trailers on the go, and reduces unnecessary grain spillage, increasing your overall grain retention.

Cross Auger Shutoff is an optional element on the S7 combines. This element automatically ensures the unload auger is completely emptied on every unload, reducing weight in the auger.

Another way John Deere ensures better productivity is with the 400-bushel 14,095-liter) grain tank, ensuring less time unloading and more time harvesting.

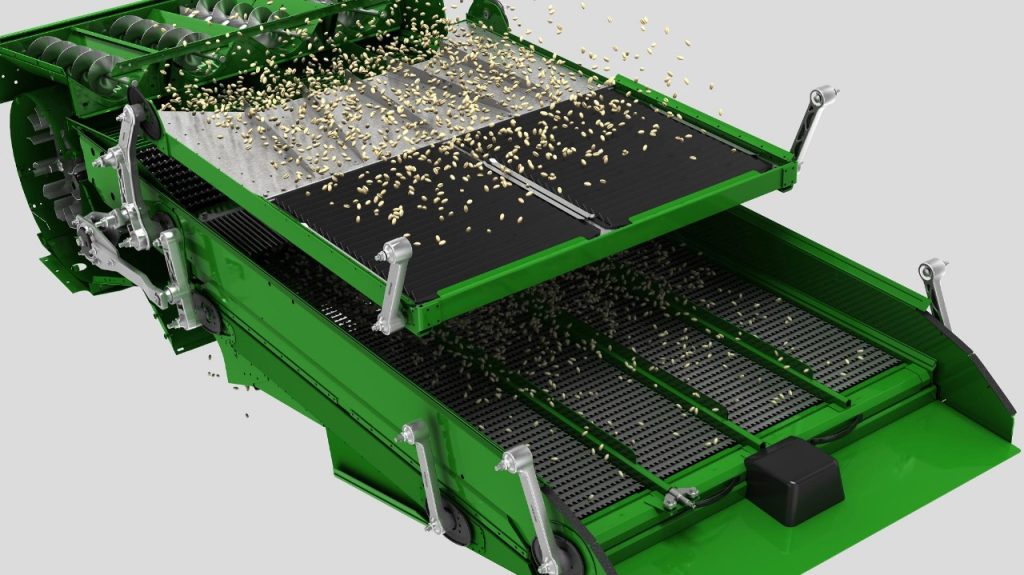

The Dyna-Flo™ Cleaning Shoe is designed to deliver clean grain when threshing and separating. This element offers uniform distribution with a unique two-stage pre-cleaning design.

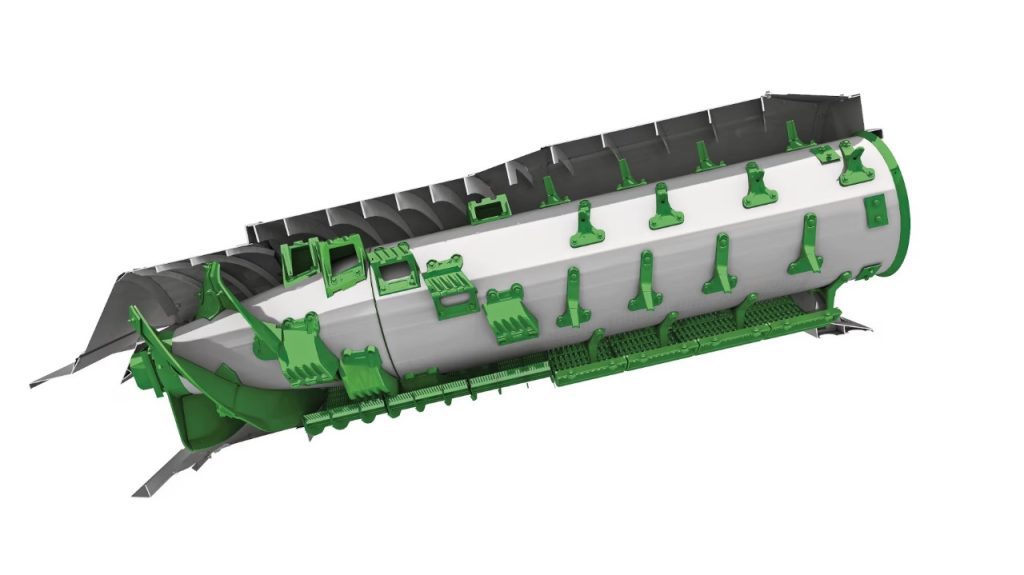

The TriStream™ Rotor is standard equipment and move large volumes of crop material resulting in increased productivity. Featuring a slightly tapered front nose, spiral vanes around the rotor guide crop material through the feeding and threshing area.

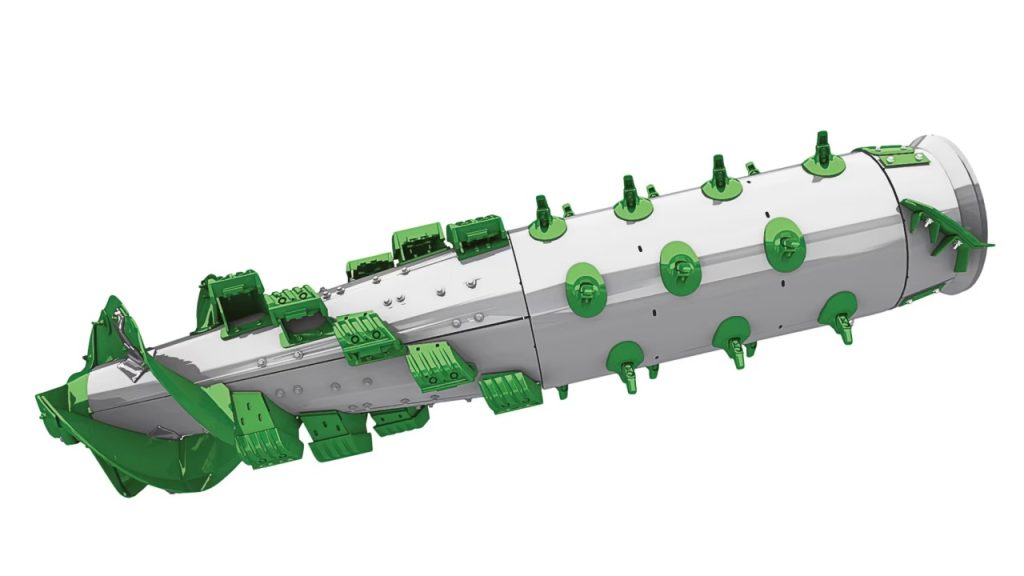

Variable Stream Rotor is Optional equipment. It delivers high capacity and smooth performance for small grain and rice operations. The design of this rotor makes it well-suited for rice where conditions are damp, wet, or extremely green.

3. COMFORT & CONTROL:

In-Base Technology:

Integrated G5Plus CommandCenter™ Display:

Upgrades to the G5Plus Display includes seeing more and easily making machine adjustments with a 35% larger screen, fast processor for quick boot times and 1080p HD resolution.

The G5 Advanced package is also available, more info at https://www.deere.com/en/technology-products/precision-ag-technology/guidance/advanced-technologies/

StarFire™ Receiver with optional SF-RTK activation:

A multi-constellation satellite signal delivers accuracy up to 2.5 cm and up to 73% faster pull-in times. Long-term repeatability minimizes guidance line, coverage, and boundary drift year after year.

New Generation Primary Display:

Bigger than previous models to give you bright, clear digital readouts of your combine’s critical information.

Talking about comfort and control. There are Comfort Packages available, starting at the select package and going through to the ultimate package. For more information on these packages visit the link and find out more https://www.deere.com/en/harvesting/s-series-combines/comfort-and-convenience-packages/

Check out our social media pages to see more of what we’re up to!